Why Winemakers Have Adopted Steam Sterilization

Winemakers must sanitize winemaking equipment properly to maintain the wine’s quality. Traditionally, winemakers relied on chlorinated materials, trisodium phosphate (TSP), and soda ash solutions to sterilize barrels and tanks. However, contemporary winemaking has shifted towards safer, more effective methods, such as winery steam. It offers a sustainable and highly effective alternative, addressing critical concerns and setting exceptional sanitation standards.

Learn more about why winemakers are adopting steam sterilization over other methods.

Elimination of Chlorinated Water for Sanitization

In response to this revelation, chlorine-based cleaning products were phased out. Companies pivoted towards ozone treatment and dry steam sterilization, alternatives to upholding stringent hygiene standards.

Why Steam Is Better for Winemaking

By adopting this innovative approach, wineries improve aromas and flavors, reaping the benefits of steam cleaning and improving the winemakers’ quality, sustainability, and reputation.

Steam vs. Ozone Treatment

Dry steam, created at high temperatures without extra moisture, efficiently cleans wine barrels, tanks, and equipment without toxic chemicals. Steam sterilization helps wineries address both water conservation concerns and health and safety concerns.

Steam vs. Conventional Cleaning Agents

Using dry steam for cleaning minimizes the environmental impact of sanitization. Compared to traditional methods, steam cleaning uses very little water, avoids introducing chemicals into production, and produces wastewater that is not toxic. These benefits make steam sterilization an appealing choice for companies aiming to showcase their commitment to sustainability.

Unlike conventional cleaning agents that need time to work on surfaces, wine barrel steamers are much quicker, resulting in significantly less downtime and more efficient use of labor. Steam sterilization also helps wineries eliminate the risk of chemical residues affecting wine flavors.

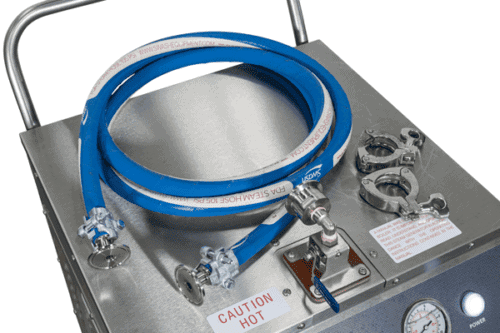

Learn More About Our Steam Generators for Winemaking

Steam sterilization is the best way to effectively clean wine equipment. It is safer, more efficient, and more effective than conventional cleaning agents and ozone treatments. Electro-Steam is a leading provider of steam generators, with a variety of models and accessories to meet your winery’s needs. When you get your steam generators from us, you can expect:

- Standard 5-year warranty on chambers and 1-year warranty on all other components

- Standard stainless steel cabinet and electrical panel

- 98% efficiency without feedwater preheating

- 2-4 week production

- ASME, CRN, UL, cUL or CE compliance

Contact us to learn more about our winery steam cleaning solutions.

Proudly Manufactured in the USA

Proudly Manufactured in the USA