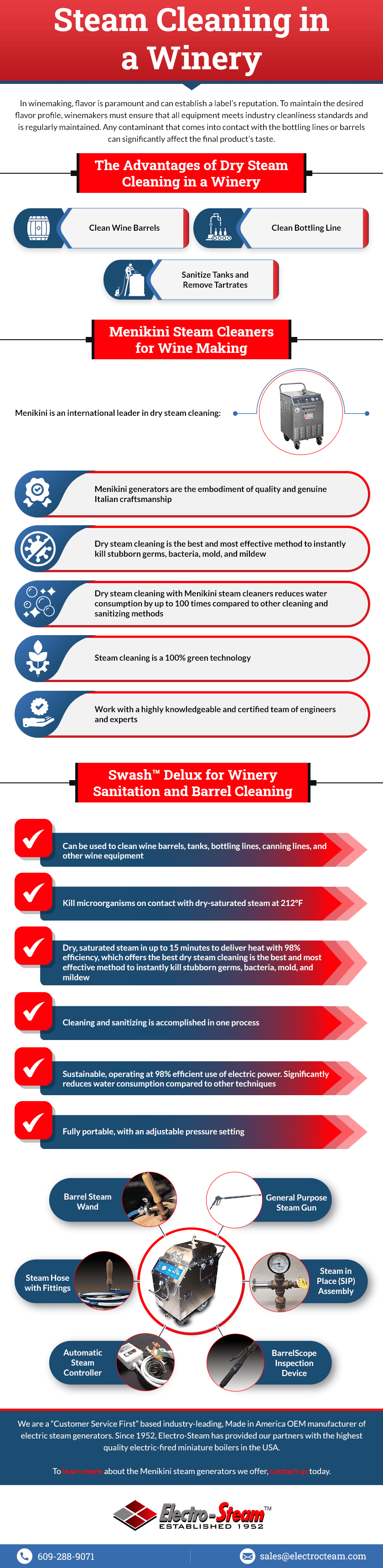

In winemaking, flavor is paramount and can establish a label’s reputation. To maintain the desired flavor profile, winemakers must ensure that all equipment meets industry cleanliness standards and is regularly maintained. Any contaminant that comes into contact with the bottling lines or barrels can significantly affect the final product’s taste. However, steam action is an effective method in winemaking to clean and sanitize these surfaces. With the right steam jet system, wineries can effortlessly eliminate the most difficult chemical agent residues, bacteria, and other tough deposits that may be otherwise hard to remove using traditional cleaning methods. Wineries also have other areas that only steam can clean and sanitize, such as flanges, taps, and pipes.

How Winemaking Steam Generators Work

Our electric steam generators produce dry, saturated steam that does not contain any boiler additives. They are designed to heat surfaces in a clean way to eliminate microbes and sanitize wine bottles, barrels, and bottling lines — without leaving behind any trace elements that could affect the wine’s taste.

The steam generators work by delivering heat through a rapid process of condensation. While hot water gives up its heat through absorption, which is a slow process, steam quickly generates enough heat to destroy the proteins that form microbe cell walls. As a result, any surface the steam comes into contact with is sterilized, even porous materials.

Converting a volume of water into steam involves the principle of latent heat of vaporization. When steam comes into contact with a lower-temperature surface, it condenses almost instantly and the latent heat is absorbed into the material. This process is why surfaces can be heated much more efficiently with steam than with water.

Converting a volume of water into steam involves the principle of latent heat of vaporization. When steam comes into contact with a lower-temperature surface, it condenses almost instantly and the latent heat is absorbed into the material. This process is why surfaces can be heated much more efficiently with steam than with water.

Electro-Steam’s electric steam generators feature a pressurized chamber that facilitates efficient steam production. It also delivers significantly greater amounts of heat compared to a hot water heater and does so much faster and with significantly less water consumption. For winemaking applications, we offer electric steam generators with carbon steel tanks and brass or copper piping that can be connected to a tap water feed. The steam produced by these generators requires no boiler additives and is referred to as Culinary Grade Steam.

Winemaking and Bottling Steam Generators from Electro-Steam

Electro-Steam offers a range of industry-leading winemaking and wine-bottling steam generators. Our products ensure the thorough and efficient sanitization of many winemaking components, including bottling lines, floors, barrels, tanks, and more. If you’re uncertain which model is right for your application, reach out to our team for help.

Menikini Steam Cleaners for Winemaking

Menikini is an international leader in dry steam cleaning technology and the largest steam generator producer in Italy. Its electric dry steam generator, the Menikini Steam Master Wine, was developed for cleaning and sanitizing many types of winemaking production spaces and equipment, including:

Menikini is an international leader in dry steam cleaning technology and the largest steam generator producer in Italy. Its electric dry steam generator, the Menikini Steam Master Wine, was developed for cleaning and sanitizing many types of winemaking production spaces and equipment, including:

- Wine and oil cellars

- Wine barrels, barriques, and tonneaux

- Steel tanks

- Bottling lines

- Filters, housings, and connectors

- Pipes

This eco-friendly sanitization tool features soft wheels designed to glide along uneven floors with ease and durable stainless steel construction. Menikini generators deliver quality Italian craftsmanship for efficient sanitization of winery systems. Key specifications include:

- High/low-pressure selector

- Low level cut-off with alarm

- Low pressure 1.3 bar (19 psi) for wooden barrels

- High pressure 5.5 bar (80 psi) for steel tanks

- 7.5 bar (109 psi) safety relief valve

- CE-compliant

To learn more about Menikini steam cleaners for winemaking, visit our online catalog.

SWASH™ Sanitizing Equipment for Winery Sanitation and Barrel Cleaning

SWASH™ Portable Steam Generators are developed by ARS Enterprises and manufactured by Electro-Steam specifically for food and beverage industry usage. These electric generators create saturated, dry steam in as little as 10 to 15 minutes. They deliver heat with 98% efficiency and unlike in fossil fuel boilers, do not lose energy up the flue.

SWASH™ Portable Steam Generators are developed by ARS Enterprises and manufactured by Electro-Steam specifically for food and beverage industry usage. These electric generators create saturated, dry steam in as little as 10 to 15 minutes. They deliver heat with 98% efficiency and unlike in fossil fuel boilers, do not lose energy up the flue.

SWASH™ steam generators are all electric and do not feature an open flame, create fumes, or require combustible fuel and fuel storage. This results in a much safer working environment, as well as lower insurance rates than with fuel-fired boilers. SWASH™ generators have an adjustable pressure setting with an easy-to-read pressure gauge display, allowing them to be used throughout a diverse range of high and low-pressure applications. They also feature a sanitary steam outlet port with a ball valve to ensure simple hookup to other types of equipment and accessories.

SWASH™ steam generators were developed with portability in mind. They feature an ergonomic design with large-diameter rear wheels that are easy to maneuver in tight spaces. These unique features make them easy to transport directly to the area where they’re needed, eliminating long hot steam lines that lose heat energy and reduce efficiency.

This durable equipment is constructed with a 304 stainless steel cabinet to both isolate and insulate the tank. Its piping is easily accessible for service yet safely out of reach during operation. It features an easy-to-clean design, with built-in wand and gun holders for convenience, as well as cord and hose brackets. Other specifications include:

- Low-level cut-off with alarm

- High/low pressure selector

- High pressure 5.5 bar (80 psi) for steel tanks

- Low pressure 1.3 bar (19 psi) for wooden barrels

- 7.5 bar (109 psi) safety relief valve

- ASME compliant

To learn more about SWASH™ sanitizing equipment, visit our online catalog.

The Advantages of Steam Cleaning in a Winery

The most important thing about winemaking is achieving and maintaining that rich taste. This is why steam cleaning is the most trusted and effective method of deep cleaning winery equipment. Some advantages of using dry steam cleaning include:

Using Dry Steam Technology to Clean Wine Barrels

Oak barrels are one of the greatest investments a winery can make. Using steam to clean the wine barrels can help maintain their longevity and rejuvenate them safely and cost-effectively.

Using Dry Steam Technology to Clean the Bottling Line

Steam evenly diffuses through the bottling line without facing significant constraints such as the effect of gravity. Steam is also safe and effective for cleaning critical parts of the bottling line system, such as the spouts and filters.

Using Dry Steam Technology to Sanitize Tanks and Remove Tartrates

Tartrates and other harsh substances tend to stick to the walls of the storage tanks. Steam quickly melts away any residues in the storage tanks. Condensation then drains the residues from the bottom of the tanks, leaving the tank thoroughly sanitized without the use of harsh chemicals.

The Portable Steam Generator Accessories

In addition to our selection of steam generators, we also offer an assortment of compatible accessories (sold by ARS Enterprises) designed to assist with many winemaking applications:

- Automatic steam controllers: Sterilize bottling lines and filter block assemblies without needing any personnel to start the process. Automatic steam controllers turn on and shut off automatically. Dual controllers are also available for sterilizing bottling lines and filter block assemblies separately.

- Barrel steam wands: Developed with the unique needs of barrel sterilization in mind, these wands release steam safely and uniformly to effectively sanitize and remove tartrates. These wands’ technique ensures that residual wine is removed from the wood’s pores with little to no erosion of the toast.

- Steam guns: Featuring a 42 in. lance, these steam guns were developed to safely clean hard surfaces and are insulated to protect the operator. They are particularly effective on floor drains.

- Steam hose with fittings: Designed for food contact, this cleaning accessory is safe for all winemaking applications. It connects directly to the steam generator as well as to any additional accessories. This steam hose is rated to 100 psi and can handle temperatures up to 338 °F (170 °C).

- Steam-in-place (SIP) assemblies: Turn any length of stainless steel sanitary pipe into an autoclave with these SIP assemblies. Applying low-pressure steam at no more than 20 psi allows internal pipe temperatures to maintain an excess of 250 °F (121°C), achieving medical-grade sterilization.

Certifications and Safety

When purchasing any type of pressurized steam generation system, safety should always be a primary concern. Steam generators for winemaking contain many internal components that must reliably withstand high pressures and high temperatures. Everything from the pumps to valves, hoses, and plumbing connections must be designed and fabricated in compliance with section I of the ASME Boiler & Pressure Vessel Code.

At Electro-Steam, all of our steam generators for winemaking meet these demands and are built with care by an ASME certificate holder. In addition, all of our products are CSA-, UL-, or CE-approved for electrical safety within the US, Canada, and EU. Since it’s common for code changes to occur over time, we invest heavily to ensure our equipment remains compliant with the latest standards, so you can purchase with confidence.

To learn more about ASME requirements for steam generators, visit our blog article on this topic.

Superior Steam Cleaning with Electro-Steam Generators

Sanitizing and sterilizing are vital in eliminating unwanted organisms and bacteria in stainless tanks, wine barrels, bottling lines, and other parts of your winery system. Hot, dry steam can easily penetrate the tiniest pores on the inside of the barrels, thoroughly sanitizing the system using high temperatures and quick condensation.

Work with Electro-Steam’s expert team to find a solution for all your needs. Contact us today for more information on Menikini, Swash, and other steam cleaning systems.

Proudly Manufactured in the USA

Proudly Manufactured in the USA