As the cannabis industry continues to evolve, reliable cleaning and processing systems that adhere to strict regulations, while maximizing efficiency, and promoting sustainability are necessary.

The production of cannabis creates contaminants, algae, and resins that can coat distillation equipment, hydro flasks, containers, tubes, irrigation systems, and other essential tools. While hand-washing the equipment was once considered the optimal choice to ensure a clean environment, the task was time-consuming and strenuous. Ultrasonic cleaning of cannabis production equipment is a game-changer for the growing industry.

Electro-Steam has been a clean steam generator manufacturer since 1952. We use only the best quality parts available for our Made-in-America products, which are assembled by boiler operators licensed by the New Jersey Department of Labor.

Our clean steam generator is safe to use in the cannabis industry, economical to operate, and easy to maintain.

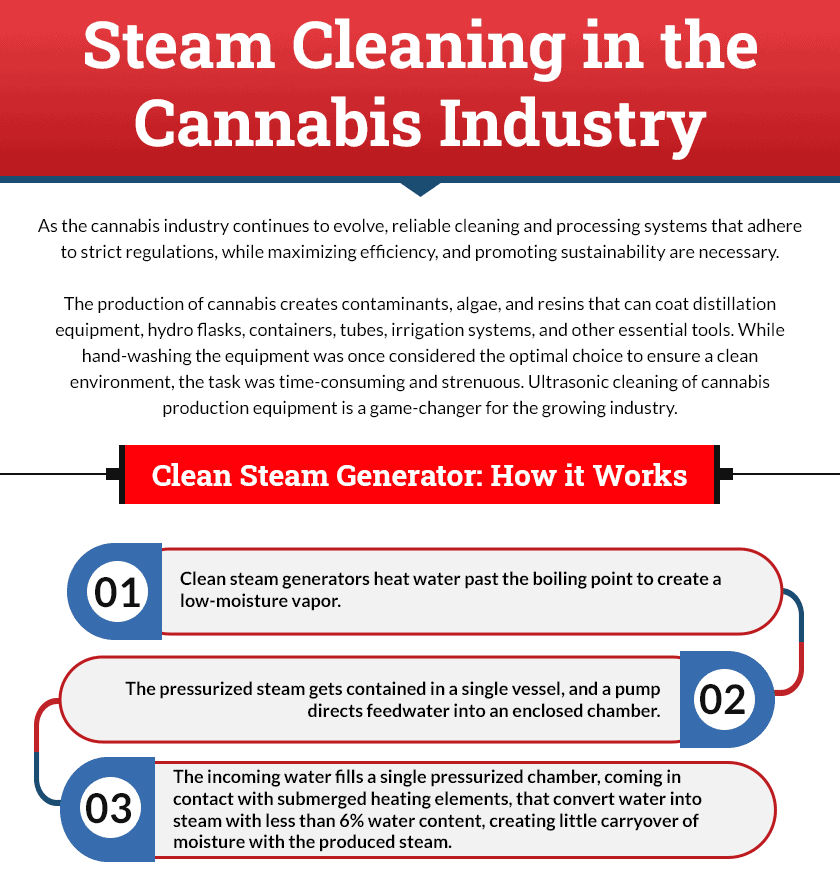

Clean Steam Generator: How it Works

Clean steam generators heat water past the boiling point to create a low-moisture vapor. The pressurized steam gets contained in a single vessel, and a pump directs feedwater into an enclosed chamber. The incoming water fills a single pressurized chamber, coming in contact with submerged heating elements, that convert water into steam with less than 6% water content, creating little carryover of moisture with the produced steam.

Clean steam generators differ from steam boilers in size, application, and operation and are effective as auxiliary boilers for maximum efficiency. They are an optimal choice for on-demand situations and are smaller,easier and safer to run than traditional steam boilers.

An electric generator is the best choice for applications requiring point-of-use dry steam since they do not typically have the same utility and safety requirements of a fuel-fired boiler. Most processes in the cannabis industry do not require the use of a large fuel fired boiler, a portable clean steam generator or a stationary clean steam process generator are the best tools on the market for operating efficiently.

As one of the top clean steam generator manufacturers in the country, Electro-Steam recommends the use of an electric clean steam generator as opposed to a fuel-fired steam boiler for the following reasons:

- Safety

- Portability

- Energy efficiency

- Quick start / on-demand steam

- Cost

Applications for Steam Cleaning in the Cannabis Industry

Electro-Steam’s clean steam generators can prove advantageous in the cannabis industry in the following ways:

Sterilization

Surgery centers, hospitals, laboratories, and pharmaceutical production facilities utilize steam sterilization for their cleaning processes. As with the medical industry, the cannabis sector must maintain strict cleanliness standards for its tools and equipment to ensure the quality and safety of the product.

Whether you need to replace, for example, a steam supply for an existing autoclave or implement a new system, Electro-Steam can design a unit to meet your processes needs. We manufacture stand-alone systems and integral units that fit inside or under cabinets or in small utility rooms. In both styles, steam gets directly piped into the process, creating an efficient creation of steam supply.

Humidification

In the cannabis industry, it is important to maintain consistent humidity levels in grow houses to allow the plants to thrive. Low humidity levels can stunt the plants’ growth and slow photosynthesis, while high humidity can cause issues such as mineral deficiencies and soft growth. Electro-Steam’s clean steam generators can maintain a comfortable environment that encourages plant growth.

Our units are an excellent choice to supply humidity for cannabis applications, offering safe, efficient, high-quality humidity.

Process Clean Steam

Process steam is a cost-effective energy source often employed by specialized systems in the manufacturing sector. Unlike other energy sources, its advantages include:

- Easier transportation

- Lower toxicity levels

- Higher heat production efficiency and capacity

- Lower production costs

For more than 60 years, Electro-Steam has designed and manufactured high-quality electric-fired miniature boilers. Hospitals, factories, laboratories, and other industrial facilities have utilized process steam, and it is a beneficial choice for cannabis production applications.

The compact design does not require venting, does not use combustible fuel, and can handle a broad range of flow rates and pressure requirements. In addition, there is no need for expensive piping or long steam lines.

Process steam systems play a crucial role in commercial and industrial applications, and Electro-Steam offers a large selection of products to accommodate our customer’s needs.

Custom Requirements

Companies around the world are taking advantage of Electro-Steam equipment for a vast range of custom applications. We have experience with many specialized situations and can help you develop an electric steam generator system for your cannabis production, sterilization or cleaning needs.

Our custom clean steam generators are available in the following PSI pressure ranges:

- 0 to 150 PSI add 0-15 and 0-100

- 0 to 200 PSI

Our units have Kilowatt ratings ranging between 40 and 240 (4 Bhp to 24 Bhp) and are available in 316L stainless steel.

Uses of Steam in the Cannabis Industry

Steam distillation is not only the most versatile form of distillation but also the most efficient. The process determines how compounds vaporize at varying temperatures. Unlike other extraction methods where oil and water solubility play a role, distillation separates various matter from the plant.

The compounds included in the distillate will vaporize at or below the distillation temperature and contain essential oil compounds, organic acids, and other water-soluble plant compounds. The byproduct of essential oil production from plants, including cannabis, are called:

- Floral water

- Colloidal suspensions (hydrosols)

- Dydrolate

- Herbal water

- Essential water

The aqueous byproducts and water-soluble components obtained by steam are referred to as hydrodistillation when discussing plants, herbs, and cannabis.

Distillates are also effective sources for cosmetics products, pharmaceuticals, and flavorings. Herbal distillates utilize the same process as extracting essential oils, but the term essential water for the byproduct is more descriptive.

Compounds with a higher boiling point, such as flavonoids and water-soluble plant pigments, remain behind. Diluted essential oils become herbal waters, and aromatic chemicals create distillates containing more plant acids than found in essential oil, creating a skin-friendly compound.

For the cannabis industry, steam is the most versatile and efficient form of distillation.

Advantages of Steam Generators

The electric clean steam generators manufactured by Electro-Steam offer advantages over other forms of cleaning equipment used in the cannabis industry.

- Environmentally Friendly: Our units do not emit pollutants and are 98% efficient. The superior efficiency rate results in water and energy conversation making the equipment green and cost-effective.

- Ease of Operation: Our compact units provide a range of pressure from 15 PSI low pressure to 100, 150 and 200 PSI high-pressure steam that can become operational from a cold startup in less than 15 minutes. Since there is no fuel source, there is no need for fuel storage, flue, ventilation, or boiler room creating a safer workplace environment.

- Safety: Electric clean steam generators are safer than-fuel generators since there is no exposure to potentially explosive fuel.

Proudly Manufactured in the USA

Proudly Manufactured in the USA