The Different Types of Steam in Industrial Steam Generation

Leave a CommentIndustrial facilities rely on different types of steam to manage tasks ranging from consistent heating and processing to managing sanitation. There are many steam types available, and choosing the right one for a given application is essential. At Electro-Steam, we provide steam generation systems suitable for a wide variety of industrial steam needs. This guide will break down the different types of steam frequently used in industrial contexts to help you find the type you need for your facility.

Types of Steam

Learn more about the different benefits and applications of these common types of industrial steam.

Dry Steam

Saturated Steam

Saturated steam is a specialized type of dry steam. While there may be some liquid remaining in the vapor, it can be easily trapped and contained. In saturated steam, the steam is at boiling point (212 °F) at atmospheric pressure or higher at increased pressure levels. Because of the relationship between pressure and temperature, steam equipment can increase the boiling point by increasing the pressure.

Saturated steam is commonly used in pharmaceutical production applications because it can provide rapid but even heating and has a high heat transfer coefficient. Operators can also fine-tune the temperature through pressure controls.

Superheated Steam

Containing less than 1% moisture, superheated steam is another type of dry steam that is hotter than its boiling point at atmospheric pressure. Superheated steam can reach higher temperatures and lower densities compared to saturated steam at the same pressure point. It can also be cooled without returning to liquid form or producing condensate.

However, there are some drawbacks to superheated steam. It can have varying temperatures even at a steady pressure and has a lower heat transfer coefficient than other steams. Superheated steam won’t release latent energy until it reaches the right level of saturation. Also, because it does reach such high temperatures, it requires specialized equipment that can handle it.

Utility Steam

Utility steam is a type of saturated steam. Most industrial steam processes use utility steam, which contains both latent and sensible energy. Unlike Electro-Steam’s equipment, traditional boilers usually treat feed water with additives that prevent it from corroding boilers or other equipment. This steam is usually classified by low, medium, or high pressure levels. In traditional boilers, utility steam also needs to run through a filter to remove rust, condensate, and other particulates that can contaminate the steam. Even then, utility steam is usually not used in direct contact with products or food but is a means to transfer energy to the relevant process.

While utility steam is used for boilers and a wide range of industrial applications, it’s not clean enough for culinary, medical, or pharmaceutical needs.

Culinary Steam

Culinary steam is regulated by the FDA to ensure any chemical additives designed to prevent rust comply with applicable health and safety regulations. It’s commonly used to sterilize surfaces used in food processing and preparation operations. Along with meeting FDA standards, culinary steam must comply with 3-A Sanitary Standards Inc. (SSI) Accepted Practice 3A-609-03, meet other company-specific policies, and use filtering systems.

Filtered Steam

Filtered steam undergoes a filtering process to remove additives or contaminants so it can be more safely used in sterilization applications.

Clean Steam or Pure Steam

Clean/Pure steam doesn’t have additives and is produced from heating purified water (RO), highly purified water (DI), or water for injection (WFI). Clean/Pure steam can be used in pharmaceutical, healthcare, and medical contexts.

Clean steam is generated by systems that use saturated steam, and the resulting condensate can be classified as water for injection, such as saline solutions. Clean steam itself can be used in other various processes such as humidification and sanitation in which contamination cannot be present. Clean steam systems are made from high-grade stainless steel components, piping, and other non-porous materials.

Choose the Right Steam System for Your Facility

Contact the team at Electro-Steam to find the right steam generation system for your needs.

How Steam Has Become a Popular Way to Sanitize Food Processing Equipment

Leave a CommentDry steam sanitizing is a widely used cleaning method for a wide range of food and beverage applications. Commercial steam cleaning for food processing equipment is versatile and efficient, offering many benefits for companies across the food supply chain.

Here we’ll look at food safety challenges and how dry steam sanitizing can help meet them.

Challenges of Meeting Food Safety Standards

The 2011 Food Safety Modernization Act (FSMA) sets requirements for sanitization and food safety best practices in food processing and related facilities. While cleanliness and response to foodborne illness outbreaks have always been emphasized, prevention of foodborne illness is the major priority of this legislation.

As a result, food growers, manufacturers, producers, packagers, and transporters must do all they can to protect their products from pathogens. This is in addition to keeping equipment and facilities clean from oils and grease, food residues, insects, and allergens to avoid contamination.

How Dry Steam Mitigates Those Challenges

To keep up with the strict requirements of the FSMA, many facilities turn to dry steam sanitization. Unlike water or wet steam, such as the steam produced during cooking, dry steam is slightly superheated so that it contains less than 10% moisture content.

A dry steam generator produces hot-dry steam, which is sprayed at high pressures and temperatures on and into equipment to clean and sanitize it quickly without chemicals, or in some cases, disassembly. As the steam evaporates, it leaves little to no moisture behind so that surfaces are clean, dry, and ready to be used again, much faster than traditional methods.

Dry steam can be used for applications like:

- Degreasing oils and fats

- Sanitizing multiple surfaces, floors, conveyor belts, and food equipment

- Killing pathogens including listeria and E.coli

- Killing molds

- Cleaning and removing residues and traces of ingredients

There are many benefits of steam sanitization. It is especially useful in settings where equipment, ingredients, and products must stay dry like bakeries, dry and powdered ingredient processing facilities, and packaging operations. Steam reaches areas inside and around equipment that are difficult to clean with other methods. Dry steam cleaning also reduces the time for drying and reassembling equipment so it can be brought back online quickly.

Our Steam Generators for Food Processing Cleaning

At Electro-Steam, we manufacture multiple types of steam sanitization systems for use across the food and beverage industry. Options include:

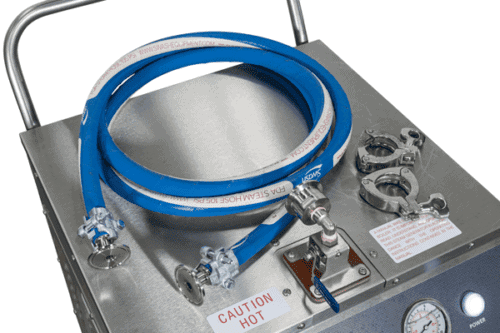

Eagle Series Dry Steam Cleaners

- Dual pressure controls (UL 353 compliant)

- Low level cut-off (LLCO) (UL 353 compliant)

- Safety relief valve with ASME V mark (built by an ASME-certified manufacturer)

- A steam gun/20-foot hose combo and a 52-tool accessories kit are included with every unit

Steam Master Series by Menikini

- Automatic pressure control

- Low level cut-off (LLCO) with alarm

- Solution/detergent tank

- Adjustable temperature regulator

- 12 Bbr (174 psi) safety relief valve

- A steam gun/20-foot hose combo and a 52-tool accessories kit are included with every Steam Master

Conveyor Belt Cleaning Systems

Electro-Steam’s fully automated or robotic conveyor belt cleaning systems simplify the process of cleaning and sanitizing conveyor belts without chemicals and without dismantling the belt systems. These systems use FDA-approved materials that can clean vinyl, mesh, and plastic conveyor belts to meet the highest industry standards. They also utilize much less water than traditional cleaning methods, saving facilities between 95%-99% of their normal water allocation for conveyor belt sanitizing.

Learn More About Steam Sanitization for Food Processing

Steam sanitization is an efficient, trusted method for cleaning and sanitizing equipment while ensuring food safety. Using the right equipment from Electro-Steam for your operations saves time, money, and labor while complying with industry regulations.

Our expert team can help you select the ideal solution for your facility and application. Contact us today to learn more about our dry steam solutions.

Why Winemakers Have Adopted Steam Sterilization

Leave a CommentWinemakers must sanitize winemaking equipment properly to maintain the wine’s quality. Traditionally, winemakers relied on chlorinated materials, trisodium phosphate (TSP), and soda ash solutions to sterilize barrels and tanks. However, contemporary winemaking has shifted towards safer, more effective methods, such as winery steam. It offers a sustainable and highly effective alternative, addressing critical concerns and setting exceptional sanitation standards.

Learn more about why winemakers are adopting steam sterilization over other methods.

Elimination of Chlorinated Water for Sanitization

In response to this revelation, chlorine-based cleaning products were phased out. Companies pivoted towards ozone treatment and dry steam sterilization, alternatives to upholding stringent hygiene standards.

Why Steam Is Better for Winemaking

By adopting this innovative approach, wineries improve aromas and flavors, reaping the benefits of steam cleaning and improving the winemakers’ quality, sustainability, and reputation.

Steam vs. Ozone Treatment

Dry steam, created at high temperatures without extra moisture, efficiently cleans wine barrels, tanks, and equipment without toxic chemicals. Steam sterilization helps wineries address both water conservation concerns and health and safety concerns.

Steam vs. Conventional Cleaning Agents

Using dry steam for cleaning minimizes the environmental impact of sanitization. Compared to traditional methods, steam cleaning uses very little water, avoids introducing chemicals into production, and produces wastewater that is not toxic. These benefits make steam sterilization an appealing choice for companies aiming to showcase their commitment to sustainability.

Unlike conventional cleaning agents that need time to work on surfaces, wine barrel steamers are much quicker, resulting in significantly less downtime and more efficient use of labor. Steam sterilization also helps wineries eliminate the risk of chemical residues affecting wine flavors.

Learn More About Our Steam Generators for Winemaking

Steam sterilization is the best way to effectively clean wine equipment. It is safer, more efficient, and more effective than conventional cleaning agents and ozone treatments. Electro-Steam is a leading provider of steam generators, with a variety of models and accessories to meet your winery’s needs. When you get your steam generators from us, you can expect:

- Standard 5-year warranty on chambers and 1-year warranty on all other components

- Standard stainless steel cabinet and electrical panel

- 98% efficiency without feedwater preheating

- 2-4 week production

- ASME, CRN, UL, cUL or CE compliance

Contact us to learn more about our winery steam cleaning solutions.

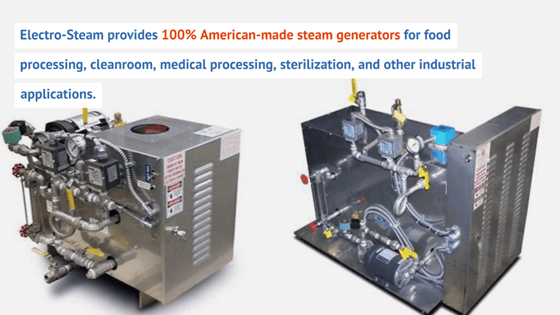

Proudly Manufactured in the USA

Proudly Manufactured in the USA