The Different Types of Steam in Industrial Steam Generation

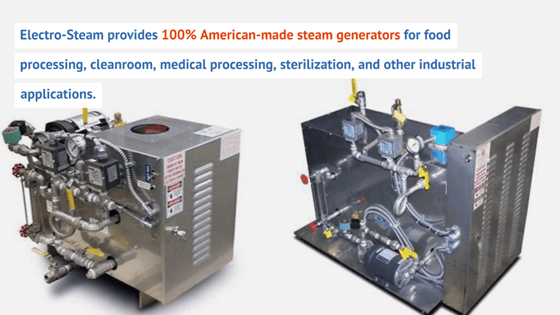

Leave a CommentIndustrial facilities rely on different types of steam to manage tasks ranging from consistent heating and processing to managing sanitation. There are many steam types available, and choosing the right one for a given application is essential. At Electro-Steam, we provide steam generation systems suitable for a wide variety of industrial steam needs. This guide will break down the different types of steam frequently used in industrial contexts to help you find the type you need for your facility.

Types of Steam

Learn more about the different benefits and applications of these common types of industrial steam.

Dry Steam

Saturated Steam

Saturated steam is a specialized type of dry steam. While there may be some liquid remaining in the vapor, it can be easily trapped and contained. In saturated steam, the steam is at boiling point (212 °F) at atmospheric pressure or higher at increased pressure levels. Because of the relationship between pressure and temperature, steam equipment can increase the boiling point by increasing the pressure.

Saturated steam is commonly used in pharmaceutical production applications because it can provide rapid but even heating and has a high heat transfer coefficient. Operators can also fine-tune the temperature through pressure controls.

Superheated Steam

Containing less than 1% moisture, superheated steam is another type of dry steam that is hotter than its boiling point at atmospheric pressure. Superheated steam can reach higher temperatures and lower densities compared to saturated steam at the same pressure point. It can also be cooled without returning to liquid form or producing condensate.

However, there are some drawbacks to superheated steam. It can have varying temperatures even at a steady pressure and has a lower heat transfer coefficient than other steams. Superheated steam won’t release latent energy until it reaches the right level of saturation. Also, because it does reach such high temperatures, it requires specialized equipment that can handle it.

Utility Steam

Utility steam is a type of saturated steam. Most industrial steam processes use utility steam, which contains both latent and sensible energy. Unlike Electro-Steam’s equipment, traditional boilers usually treat feed water with additives that prevent it from corroding boilers or other equipment. This steam is usually classified by low, medium, or high pressure levels. In traditional boilers, utility steam also needs to run through a filter to remove rust, condensate, and other particulates that can contaminate the steam. Even then, utility steam is usually not used in direct contact with products or food but is a means to transfer energy to the relevant process.

While utility steam is used for boilers and a wide range of industrial applications, it’s not clean enough for culinary, medical, or pharmaceutical needs.

Culinary Steam

Culinary steam is regulated by the FDA to ensure any chemical additives designed to prevent rust comply with applicable health and safety regulations. It’s commonly used to sterilize surfaces used in food processing and preparation operations. Along with meeting FDA standards, culinary steam must comply with 3-A Sanitary Standards Inc. (SSI) Accepted Practice 3A-609-03, meet other company-specific policies, and use filtering systems.

Filtered Steam

Filtered steam undergoes a filtering process to remove additives or contaminants so it can be more safely used in sterilization applications.

Clean Steam or Pure Steam

Clean/Pure steam doesn’t have additives and is produced from heating purified water (RO), highly purified water (DI), or water for injection (WFI). Clean/Pure steam can be used in pharmaceutical, healthcare, and medical contexts.

Clean steam is generated by systems that use saturated steam, and the resulting condensate can be classified as water for injection, such as saline solutions. Clean steam itself can be used in other various processes such as humidification and sanitation in which contamination cannot be present. Clean steam systems are made from high-grade stainless steel components, piping, and other non-porous materials.

Choose the Right Steam System for Your Facility

Contact the team at Electro-Steam to find the right steam generation system for your needs.

Proudly Manufactured in the USA

Proudly Manufactured in the USA