Proper maintenance and cleaning of conveyor belts are crucial to prevent operational disruptions, profit loss, and productivity setbacks. Regular inspections help identify issues early on, minimizing downtime and repair expenses. In the food processing industry, maintaining cleanliness is vital to ensure belt hygiene and prevent potential health hazards for workers and consumers. However, certain belts may pose cleaning challenges, necessitating the use of appropriate solvents and techniques to meet sanitation standards.

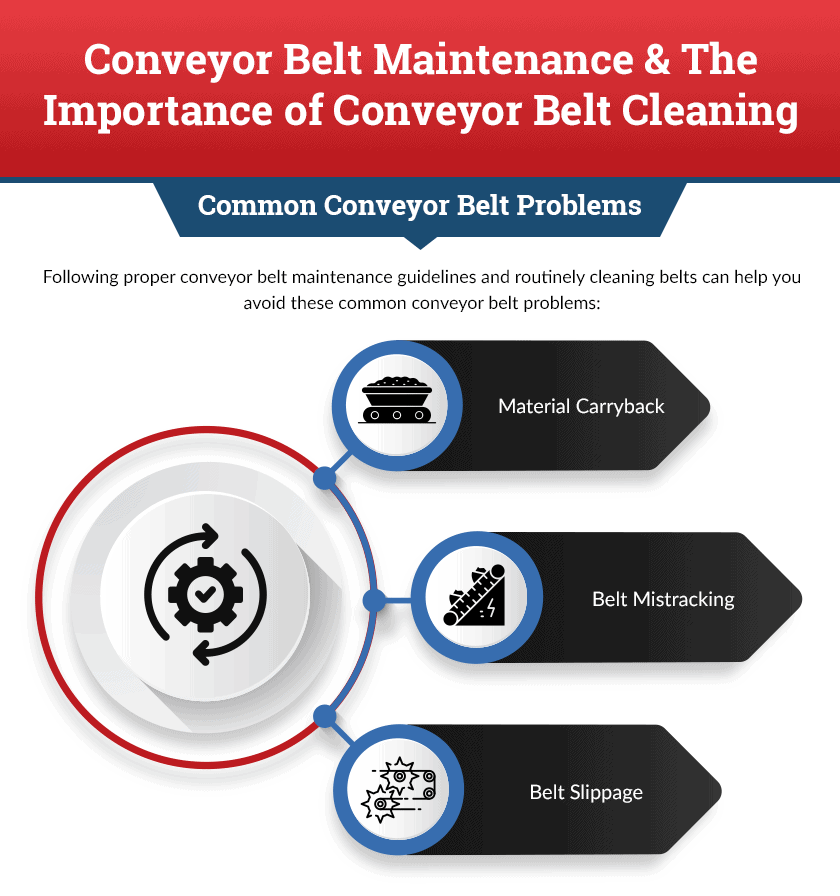

Common Conveyor Belt Problems

Material Carryback

As the name implies, material carryback is when the material on the conveyor belt is not discharged and gets carried back on the return. It can cause significant damage to other conveyor components and contribute to the contamination of new product.

The most common reasons for material carryback include:

- Poor quality or improperly installed scrapers

- Inappropriate scraper type and size

- Poor sanitation methods

Belt Mistracking

Belt misalignment is a common issue that occurs when a conveyor belt deviates from its intended track, causing it to pull to one side. Belt mistracking can damage other system components and the belt and cause potential material spillage.

Common causes of belt mistracking include:

- Material overload on the belt

- Locked rollers or misaligned idlers or locked rollers

- Faulty chute structure skirting

- Crooked or worn belt splices

Belt Slippage

Conveyor belts require precise tension because too much or too little can cause the belt to slip off the pulleys. This is referred to as belt slippage and it can cause belt or motor damage. Therefore, it’s important to set the conveyor belt’s tension to the manufacturer’s specifications.

Belt slippage is often caused by:

- Improperly installed head drive pulley or worn lagging

- Material overload on the belt

- Damaged tail pulleys or wing

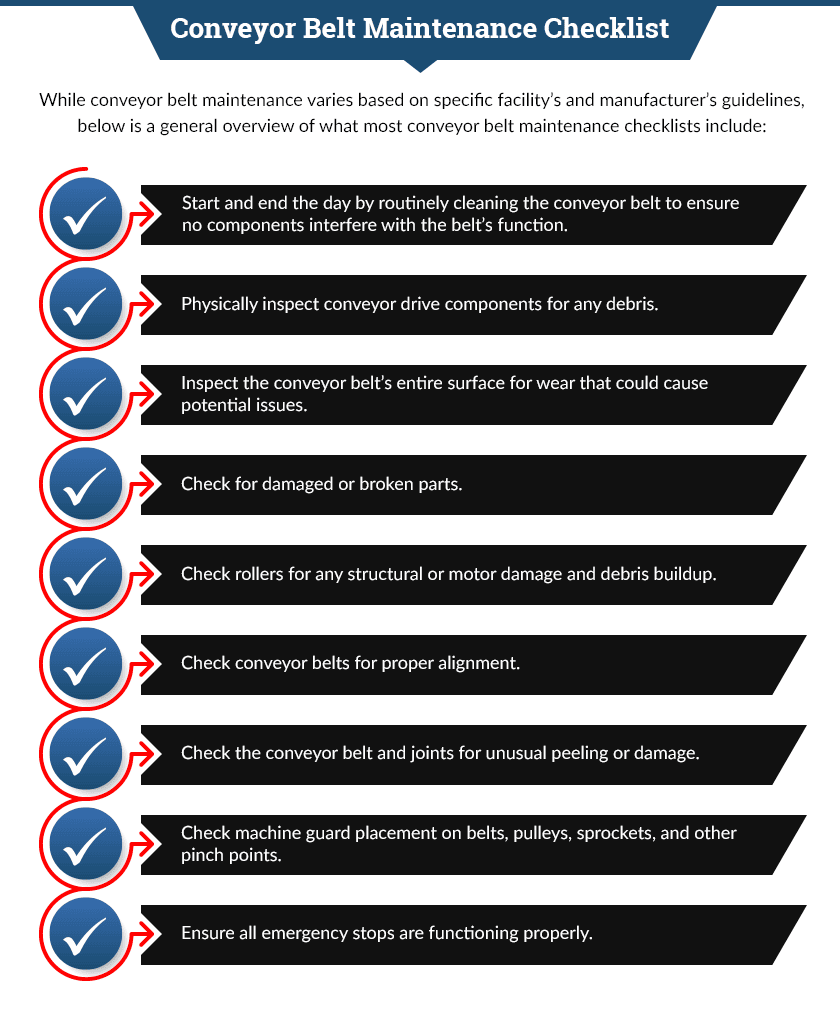

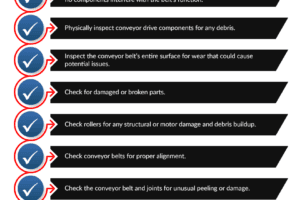

Conveyor Belt Maintenance Checklist

While conveyor belt maintenance varies based on specific facility’s and manufacturer’s guidelines, below is a general overview of what most conveyor belt maintenance checklists include.

- Start and end the day by routinely cleaning the conveyor belt to ensure no components interfere with the belt’s function.

- Physically inspect conveyor drive components for any debris.

- Inspect the conveyor belt’s entire surface for wear that could cause potential issues.

- Check for damaged or broken parts.

- Check rollers for any structural or motor damage and debris buildup.

- Check conveyor belts for proper alignment.

- Check the conveyor belt and joints for unusual peeling or damage.

- Check machine guard placement on belts, pulleys, sprockets, and other pinch points.

- Ensure all emergency stops are functioning properly.

Electro-Steam Products

Modular Conveyor Belt Cleaning System

The steam cleaning technique prevents water from puddling on your facility’s floor and soiled wastewater from standard cleaning methods running to your drain. With a minimal water usage of just a few ounces per minute, the water evaporates before reaching the floor, resulting in a pile of damp soil from the conveyor cleaning process. Our Robotic Jet System is an effective, efficient, and chemical-free modular conveyor belt cleaning system that streamlines the cleaning process.

Each of our Robotic Jet Systems is fully customized for an optimal cleaning solution based on the type of carryback and soil for your application. Our powerful dry vapor steam system can handle many contaminants, including:

- Fats and oils

- Allergens

- Over-spray

- Bacteria

- Glazes

- Confectionaries

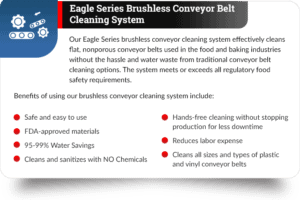

Eagle Series Brushless Conveyor Belt Cleaning System

Our Eagle Series brushless conveyor cleaning system effectively cleans flat, nonporous conveyor belts used in the food and baking industries without the hassle and water waste from traditional conveyor belt cleaning options. The system meets or exceeds all regulatory food safety requirements.

Benefits of using our brushless conveyor cleaning system include:

- Safe and easy to use

- FDA-approved materials

- 95-99% Water Savings

- Cleans and sanitizes with NO Chemicals

- Hands-free cleaning without stopping production for less downtime

- Reduces labor expense

- Cleans all sizes and types of plastic and vinyl conveyor belts

Industrial Conveyor Belt Cleaning Solutions from Electro-Steam

Ensure uninterrupted operations and prolong the lifespan of your conveyor belts with Electro-Steam’s customized maintenance and cleaning systems. Our Jet System Modular Conveyor Belt Cleaning System and Eagle Series Brushless Conveyor Belt Cleaning System are designed to meet the unique needs of modular and flat belt systems, effectively removing carryback and sanitizing surfaces. Trust our powerful solutions to exceed industry standards. Contact us today for tailored conveyor belt cleaning solutions.

Proudly Manufactured in the USA

Proudly Manufactured in the USA